Thanks to our 25 years of experience and KNOW-HOW that we have achieved over that time, we can handle even the most demanding requirements of our clients. Our experienced DEVELOPMENT TEAM and the possibility of immediate testing of prototypes provide the necessary efficiency for the production of tailored packaging solutions.

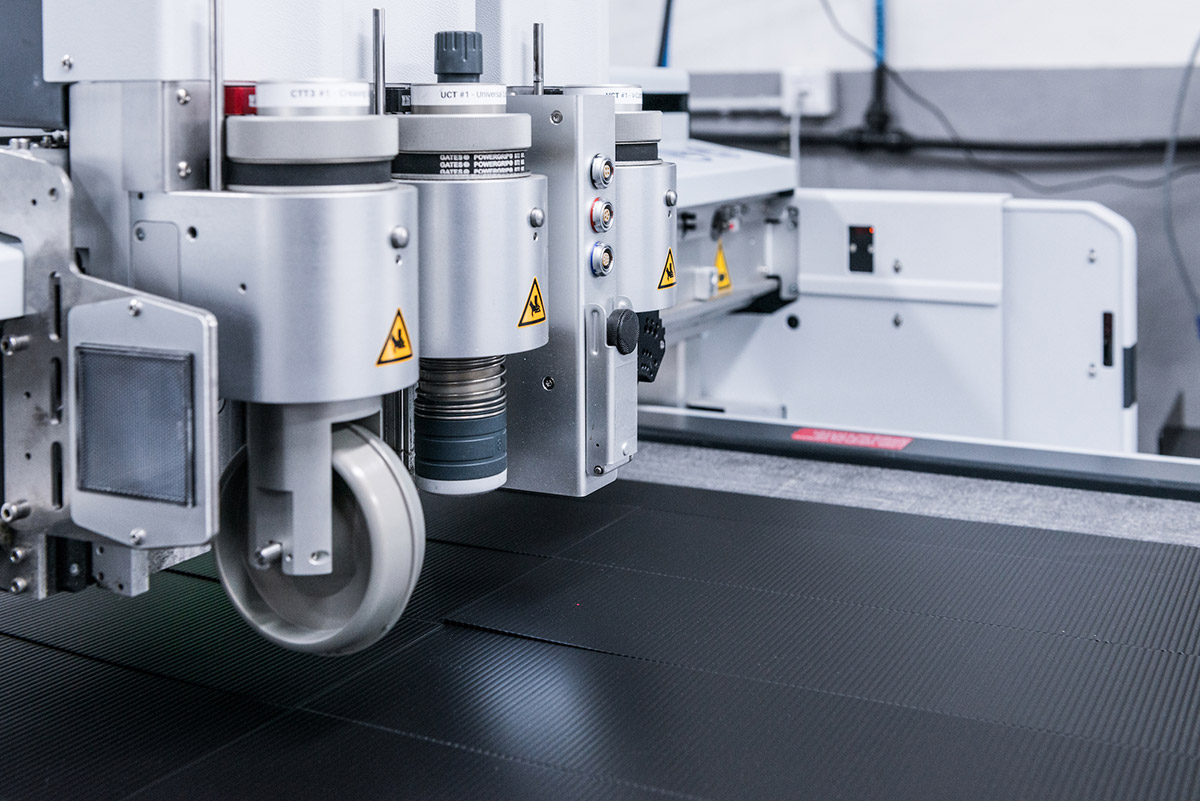

In production, we use top-notch TECHNOLOGY, modern machines and equipment, thanks to which we can produce products at a high-quality level and exactly according to our clients’ specifications.

Analysis and Research

Our starting point is the client’s assignment, which we will specify in more detail during a discussion. We need to know the function of the packaging – its purpose, required endurance, standard, etc. The first step is always to analyse the requirements and research. To do this, we need a sample of the product for which the packaging is intended, or, even better, 3D product data.

Development and Design

The next step after thorough research is to develop the product. We start with a design proposal, which is then reworked into a detailed technical plan with a construction and material solution. To do so, our creative development team uses software such as 2D/3D CAD, the Solid Works system, and Adobe Illustrator and Corel Draw to design the project. An integral part of the development is also ongoing consultations with the client.

Prototype and Testing

Once the design is completed, we then manufacture a prototype – the first sample to undergo testing. Based on our findings, the product is further modified, improved and optimised. We repeat this process until we reach an optimal solution. If we have ideas for improving the packaging in terms of material savings, storability, environmental friendliness or cost effectiveness, we proactively present our innovative proposals to the client compared to the original requirement.

Systematic production

After fixing any bugs, the client approves the final solution and we can start with the product’s systematic production. If necessary, in addition to the basic packaging solution, we are able to develop and manufacture its other replaceable components, such as textile inserts or inner fixations. For repeat customers, we can ensure the production of packaging for stock based on a framework agreement on annual purchase quantities or based on a promise to purchase goods.

Most frequently solved problems

- Optimization of transport costs of large producers

- Allocation of stored parts fot the highest possible transport efficiency

- Easy and efficient handling of packaging

- Perfect product protection during transport

- Durability of packaging and its recyclability for responsibility towards nature

- Delivery dates and systematic logistic for critical industry needs

- Price-performance ratio

Contact form

Project is co-financed from the European Regional Development fund

Project name: Reducing the energy intensity of hall H1